Discover the latest news, trends and happenings at Well Data Labs

Got casing deformation? Have you looked at your frac data?

Don’t wait until plug drill-out to discover casing deformation

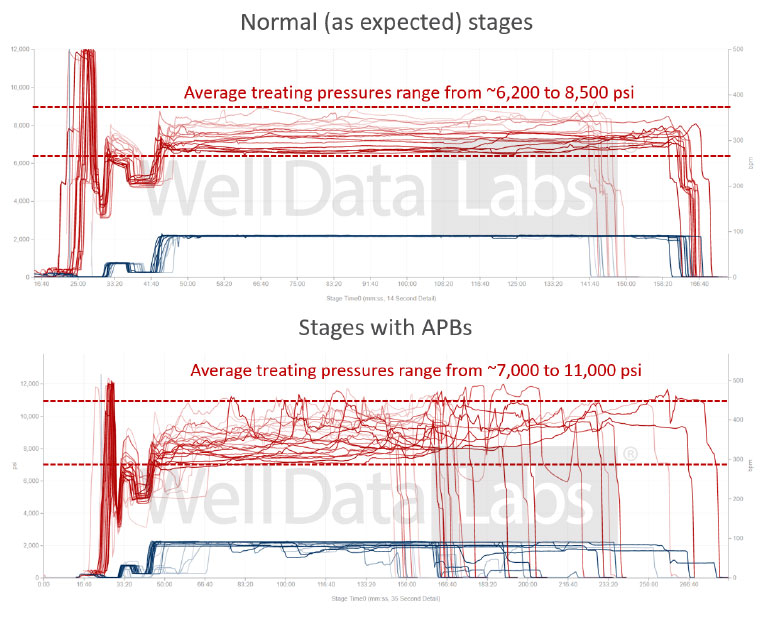

The trend in hydraulic fracturing has been to push the envelope on drilling longer horizontal laterals with an ever-increasing number of stages, clusters, proppant, and fluid volumes. As completion intensities have increased, there has been an associated increase in casing deformations leading to partial or complete restrictions in the lateral. Publications and poll surveys agree that the overwhelming majority of casing deformations occur during hydraulic fracturing operations. Until now, few case studies have examined the high-resolution fracturing treatment data to identify characteristic pressure signatures related to casing deformation or failures. read more…

The Potential of Refracturing: How a Partnership Between Well Data Labs and ResFrac Optimized Designs in the Eagle Ford Shale

The oil and gas industry is constantly seeking ways to optimize and improve production while keeping costs low and reducing environmental impacts. In the Eagle Ford shale, one of the most significant challenges faced by operators is determining the most efficient completion design for refracturing wells. When it comes to refrac design, it’s crucial to get it right the first time, as a suboptimal design can lead to decreased efficiency and profitability.

A cutting-edge approach to solving this problem involves combining state-of-the-art diagnostics such as Sealed Wellbore Pressure Monitoring (SWPM) with advanced fracture modeling. This combination – powered by a strategic partnership between Well Data Labs and ResFrac – can help operators identify the best completion design for their specific wells, ensuring maximum productivity and a strong return on investment. In this blog post, we will delve into a recent case study from the Eagle Ford shale, exploring the techniques used to optimize refrac designs and the key findings that emerged from this groundbreaking research. By understanding the insights gained from this study, operators and other stakeholders in the oil and gas industry can take informed steps towards improving the efficiency of their refrac programs and, ultimately, boosting production and profitability.

SWPM has been utilized across North and South America Basins with over 16,000 stages monitored as of mid-2022. Numerical models can now be automatically calibrated to the volume to first responses (VFRs) determined from SWPM. In this case study, fracture model calibration was performed assuming that restimulation fractures propagated independently of the previously created fractures. The modeled fracture geometries compare favorably to the calibration VFRs and the fiber strain (not used in the calibration). This process demonstrates a streamlined workflow for calibrating physics-based models to observed fracture geometries, strengthening insights from SWPM, and accelerating completion design optimization.

Considering the lessons learned and insights gained from the Eagle Ford shale case study, operators can optimize their refrac designs for maximum efficiency and production. Here are some steps you can follow:

- Leverage advanced diagnostics: Utilize Sealed Well Pressure Monitoring (SWPM) to gather information on the refrac wells’ behavior, cluster efficiency, and fracture geometry.

- Employ fracture modeling: Use advanced fracture modeling techniques to automatically history match the VFRs captured through SWPM, leading to a more accurate prediction of fracture behavior.

- Account for stage design differences: Understand that the VFR and fracture character differences are predominantly governed by stage design differences and not by heterogeneity, allowing for better optimization of completion designs.

- Consider stress anisotropy: While the case study assumed sufficient stress anisotropy, ensure your model takes into account any significant stress reorientation to achieve more accurate results.

- Identify optimal cluster efficiency: Analyze SWPM results to determine the highest cluster efficiency and confirm the findings with cross-well strain fiber data and fracture modeling.

- Understand fracture growth: Use the calibrated model to gain insights into non-dominant fracture growth, leading to a better understanding of the three-dimensionality of fracture propagation.

- Optimize completion architecture: Apply the insights gained from the calibrated model to test and improve completion architecture, leading to incremental improvements in efficiency and production.

- Match productivity with calibrated models: Implement a workflow for matching the productivity of the subject wells, which can be extended to optimize fracture design for various objectives, such as EUR, NPV, or IRR.

- Stay informed on advancements: Keep up-to-date with the latest research and advancements in refrac design, diagnostics, and modeling techniques to ensure your operations remain at the cutting edge of industry best practices.

In conclusion, the Eagle Ford shale case study highlights the importance of leveraging advanced diagnostics, fracture modeling, and data-driven insights to optimize refrac designs for maximum efficiency and production. By understanding the critical factors affecting completion designs and fracture propagation, operators can make informed decisions to enhance their operations.

Equipped with this knowledge, you can take steps to implement these strategies in your own projects, leading to increased profitability and better resource management. We are excited about our recent partnership with ResFrac to bring these joint capabilities to our customers.

Don’t hesitate to reach out to our team for more information or for further resources on this topic, and stay tuned for more developments in refrac design and optimization in the coming months.

3 tools you need to enable real-time completions decisions

Summary of the SPE HFTC 2022 paper, “Automating a Breakthrough Technology for Real-Time Diagnostics: Sealed Wellbore Pressure Monitoring”

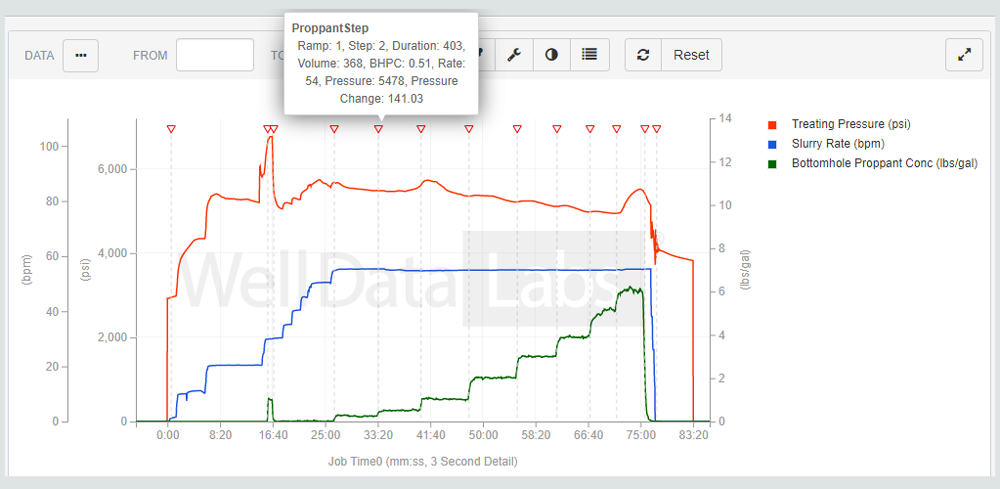

The SWPM (sealed wellbore pressure monitoring) process is precisely what the name implies – measuring pressure changes on a sealed wellbore. This technique is simple, economical, and highly accurate. A surface gauge mounted on a sealed wellbore and the Well Data Labs Completions platform provides two essential tools needed to quantify different hydraulic fracturing parameters. With the added power of machine learning, we can move even closer to real-time analysis. So, before we dive in, below is a very brief summary of Sealed Wellbore Pressure Monitoring.

SWPM 101

-

- Patented by Devon Energy

- Made available through an exclusive partnership with Well Data Labs in 2020

- 13,000+ stages have been analyzed with SWPM

- 70+ projects in 16 major North and South American unconventional basins

- Validated against multiple diagnostics including cross-well strain and fiber-optic distributed temperature/acoustic sensing

5 tips to improve your data visualizations with color

Find insights and create action faster with the right data visualizations

Visual communication skills are often an afterthought in the workplace. Still, they’re critical if your job relies on data-driven decision making. With the volume of data most industries collect these days, it’s near impossible to make sense of terabytes of data without leaning on data visualizations to abstract it.

With the help of visualizations, we can dive into tangled messes of data in a more methodical way. One main reason data scientists use visualizations is exploration or hunting for insights. Abstracting data by using visualizations can help us identify trends, spot outliers, evaluate performance, draw comparisons, and test hypotheses. We call this “data brainstorming” — a focus on discovering and testing strategic ideas through data viz. read more…

How to make the most of Sealed Wellbore Pressure Monitoring and Offset Pressure Analysis: a guide to two fracture diagnostic options

You wouldn’t use a hammer and a scalpel for the same job, and you shouldn’t use the same fracture diagnostics either.

There is no shortage of fracture diagnostic options in the market today. In fact, by our count, there are approximately 50 different methods (not providers, mind you, but technologies) that can be used as fracture diagnostics. These range from proppant tracers to microseismic and everything in between. A full analysis of the differences between these technologies and applications in the field could fill the pages of a textbook. Today, we will dive into two specific fracture diagnostics options that are near and dear to our hearts here at Well Data Labs: Sealed Wellbore Pressure Monitoring (SWPM) and Offset Pressure Analysis (OPA), with an examination of the type of data each technique provides and rough guidelines on when each makes the most sense to apply in a given situation. read more…

The PPE (Passion-Perseverance-Expertise) you need for a career in oil and gas

Jessica Iriarte, Karen Olson, and Mary Van Domelen share their insights and advice for thriving in a career in oil and gas

With a combined 85+ years of experience in the industry, Jessica, Karen, and Mary certainly have their fair share of stories and advice for navigating a career in oil and gas. From living and working in places like Italy, Norway, Cairo, and Latin America to balancing careers and personal lives, these three leading ladies of completions share some of their lessons learned and best advice. read more…

The numbers game: are more perforation clusters better?

You know what they say; more is better. But is it always?

For many years now, the most common method for horizontal multistage fracturing in tight rock formations has been Plug-and-Perf (PnP), utilizing several perforation clusters along the lateral section of the well in an attempt to create multiple fractures in any single stage. The basic assumption initially was that all clusters receive equal stimulation. However, irregularities in production performance and post-frac evaluations have led to the conclusion that the placement of these perforation clusters is critical. The number of perforation clusters has a significant impact on how effectively fractures can be created in the formation. read more…

No time? No problem! AI-enabled event picking for the win!

Automation, artificial intelligence, AI-enabled, machine learning – these words have become a part of our vernacular. And, when it comes to enhancing how we live and work, the possibilities are boundless. The Apple Watch, for example, has an app that checks for changes in heart rate. If it detects something out of the norm, it sends an alert to the doctor and patient enabling them to make informed and timely decisions about the care or action needed.

Turning to completions operations, using technology to automate manual tasks such as selecting stage start and end times can greatly benefit workflows, operational efficiencies, and decision making. First, it frees workers up to focus on higher-value, higher-impact tasks. And when adding real-time data, it can also arm teams with timely information and alerts about potential problems so they can make more proactive on-the-fly decisions. read more…

VFR, the new buzz word in the oilfield! What is it?

There’s been a lot of talk in the last eight months about SWPM (Sealed Wellbore Pressure Monitoring) with Devon’s patent-pending technology but, have you heard the acronym VFR? No, it’s not Visual Flight Rules. But, if you answered Volume to First Response, skip to the front of the line. (more…)

Making historic fracture design evaluation easier with machine learning

At the most basic level, hydraulic fracturing’s main objective is to fracture the rock to stimulate the flow of hydrocarbons. When completion engineers design a frac job, their priorities are to optimize that flow while adhering to operational, budgetary, and reservoir development constraints to maximize well performance and economics. Of course, it is much more complicated than that, and looking to the past can provide context and a better understanding of performance, which can be applied to the future. Such is the case with hydraulic fracturing data. read more…