Summary of the SPE HFTC 2022 paper, “Automating a Breakthrough Technology for Real-Time Diagnostics: Sealed Wellbore Pressure Monitoring”

The SWPM (sealed wellbore pressure monitoring) process is precisely what the name implies – measuring pressure changes on a sealed wellbore. This technique is simple, economical, and highly accurate. A surface gauge mounted on a sealed wellbore and the Well Data Labs Completions platform provides two essential tools needed to quantify different hydraulic fracturing parameters. With the added power of machine learning, we can move even closer to real-time analysis. So, before we dive in, below is a very brief summary of Sealed Wellbore Pressure Monitoring.

SWPM 101

-

- Patented by Devon Energy

- Made available through an exclusive partnership with Well Data Labs in 2020

- 13,000+ stages have been analyzed with SWPM

- 70+ projects in 16 major North and South American unconventional basins

- Validated against multiple diagnostics including cross-well strain and fiber-optic distributed temperature/acoustic sensing

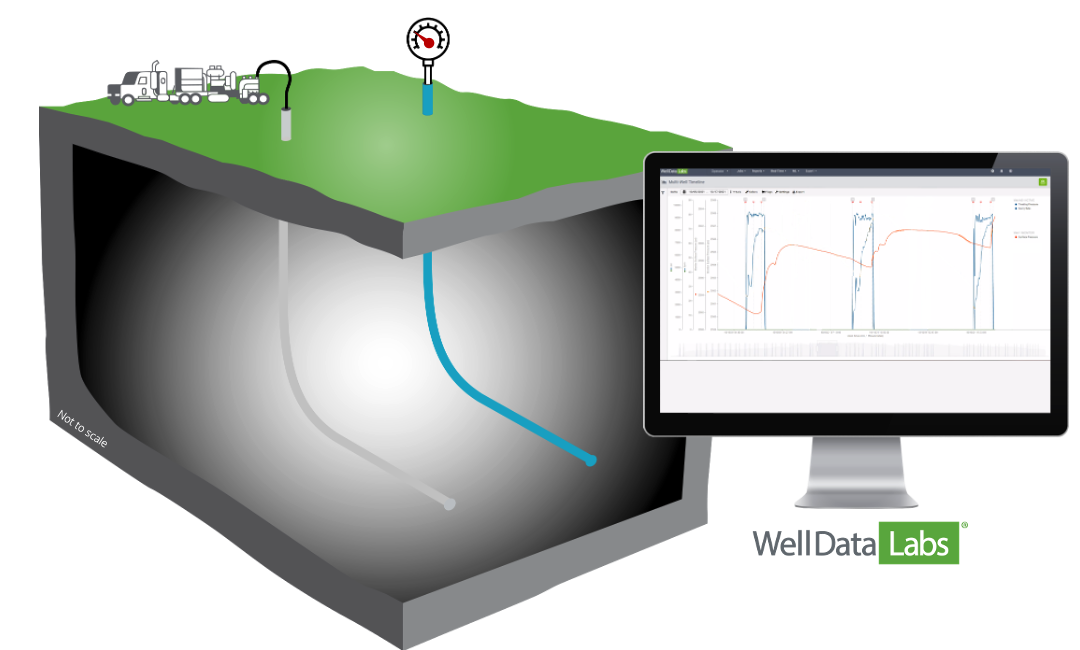

As shown in the animation below, the SWPM method is straightforward; here is a simplified explanation:

-

- A sealed wellbore is filled with fluid (typically freshwater or brine) and outfitted with a pressure gauge.

- As an adjacent treatment well is completed, fractures extend toward the sealed well, causing subtle pressure changes that can be detected by the pressure gauge.

- The pressure and fracturing data are captured and analyzed on the Well Data Labs Completions platform.

Whether performed manually or automated with machine learning, processing and analyzing pressure responses requires a dataset of high-frequency hydraulic fracturing data. Time-stamps for pressure and rate events are synchronized between the active and monitor well, ensuring that fracture-driven interactions (FDIs) align with the active operation. Identifying substantial, persistent, and positive inflections on the monitor well help pinpoint potential FDIs. However, manually picking these events has traditionally been performed post-stage, prohibiting real-time decision-making. Enter machine learning!

As a real-time fracture diagnostic, SWPM has two main requirements. First, multiple data sources must be time-synced and streamed from the field to the Well Data Labs Completion platform. The second is a robust machine learning platform. Critical completion events from the monitor well are flagged and correlated with the active operation using our machine learning modules, Power-Ups™.

This is by far more complex than what I have illustrated here. It involves coordinating multiple vendors, ensuring the various data types such as wireline and pump down are time-synced, and streaming the data to a common platform. Add the instability of data coming out of the field, and you can begin to understand some of the challenges. Yet, despite these challenges, machine learning offers a breakthrough for mapping real-time data and aiding on-the-fly decisions.

Using Real-Time SWPM in the Permian Basin

A major Permian Basin operator had an uncompleted well with poor cement along the lateral. Due to the poor cement, the team was concerned that fractures would connect with the previous stage. Thus creating “super fractures” that could extend into a nearby well, forming a poor drainage pattern and reducing well recovery.

Having performed several SWPM projects in the Wolfcamp, the operator was familiar with the technique and deployed SWPM in real-time to mitigate these “super fractures”. The goal was to test whether the poorly cemented well would trigger fracture interactions in a nearby offset well.

The operator had two pump designs prepared for the test: a standard and an alternate, smaller design. The team planned to switch to the alternate design if the real-time pressure data indicated fracture interactions between the monitor and offset wells were occurring too quickly. After the project concluded, a total of 24 stages were pumped in the well; eight were determined to have undesirable fracture interactions, six of which were identified during real-time operations. Using Real-Time SWPM, the operator was able to identify and shorten stages with fracture interactions caused by the poor cement. This saved the operator time, increased the daily stage count, and reduced the formation of “super fractures.”

Takeaways

Machine learning offers three undeniable benefits:

-

- Saves time; events are flagged in seconds rather than hours

- Minimizes bias often associated with human interpretation

- Improves analysis by providing a rapid, repeatable process

Real-time SWPM has to potential to:

-

- Provide guidance to completion engineers and wellsite supervisors to aid real-time operational decisions

- Reduce completion costs and improve operational efficiency

- Increase IOR without jeopardizing well/pad performance

Three tools needed for Real-time SWPM:

-

- Sealed wellbore

- Well Data Labs Completions platform

- Well Data Labs Machine Learning

Our technical paper, SPE-209161-MS, “Automating a Breakthrough Technology for Real-Time Diagnostics: Sealed Wellbore Pressure Monitoring” provides a deeper, far more technical explanation for engineers, data scientists, or anyone who wants to nerd out. It can be accessed from OnePetro using this link.

I would also like to acknowledge the authors of the paper: Alberto Ramirez, Damir Basic, Josh Merritt, Karen Olson, Mary Van Domelen. To learn more, visit our Fracture Diagnostic web page or check out some popular SWPM resources below.

Additional Resources

“Devon, Well Data Labs Develop New Standard in Fracture Diagnostics,” Hart Energy, November 2021

“Turning a Breakthrough Technology into a Scalable Process: Sealed Wellbore Pressure Monitoring,” SPE-204193-MS, May 2021,

“Teasing Meaning Out of a Tangle of Fracturing Data,” Journal of Petroleum Technology, February 2021

“How to make the most of Sealed Wellbore Pressure Monitoring and Offset Pressure Analysis: a guide to two fracture diagnostic options,” Well Data Labs blog post, February 2021

“Another Step Closer to Real-time Hydraulic Fracture Design,” (PDF) Hart Energy, October 2020

“Breakthrough Technology Uses Pressure Monitoring To Diagnose Cluster Efficiency,” American Oil & Gas Reporter, April 2020

“Sealed Wellbores and the Unlikely “Breakthrough” Behind Cheap, Accurate Fracture Diagnostics,” Journal of Petroleum Technology, April 2020

“Pressure-Monitoring Technique Uses Sealed Wellbore Pressure as Source,” Journal of Petroleum Technology, March 2020

“Monitoring the Pulse of a Well Through Sealed Wellbore Pressure Monitoring, a Breakthrough Diagnostic With a Multi-Basin Case Study,” February 2020, SPE-199731-MS

How can we help?

To learn more about SWPM email services@welldatalabs.com or call (720) 662-7771. To learn more about our other Professional Services, click here to visit the page.