You wouldn’t use a hammer and a scalpel for the same job, and you shouldn’t use the same fracture diagnostics either.

There is no shortage of fracture diagnostic options in the market today. In fact, by our count, there are approximately 50 different methods (not providers, mind you, but technologies) that can be used as fracture diagnostics. These range from proppant tracers to microseismic and everything in between. A full analysis of the differences between these technologies and applications in the field could fill the pages of a textbook. Today, we will dive into two specific fracture diagnostics options that are near and dear to our hearts here at Well Data Labs: Sealed Wellbore Pressure Monitoring (SWPM) and Offset Pressure Analysis (OPA), with an examination of the type of data each technique provides and rough guidelines on when each makes the most sense to apply in a given situation.

SWPM – Sealed Wellbore Pressure Monitoring

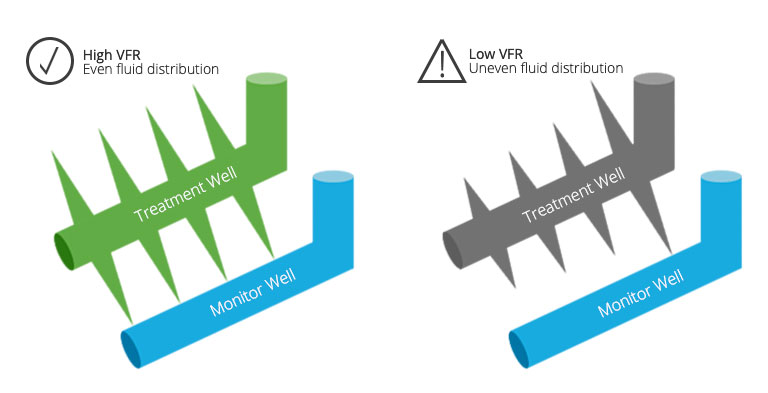

Let’s begin with SWPM. This innovative technique utilizes a sealed wellbore (filled with low compressibility fluid) to act like an underground antenna. As hydraulic fractures interact with the sealed wellbore, there are discernable pressure changes that can be picked up from within, providing valuable data. Proper SWPM execution requires establishing a closed system without perforations connected to the formation being stimulated, along with a sealed casing. With this, a surface or downhole gauge can collect and transmit the necessary data to evaluate interactions with treatment wells that are actively being completed.

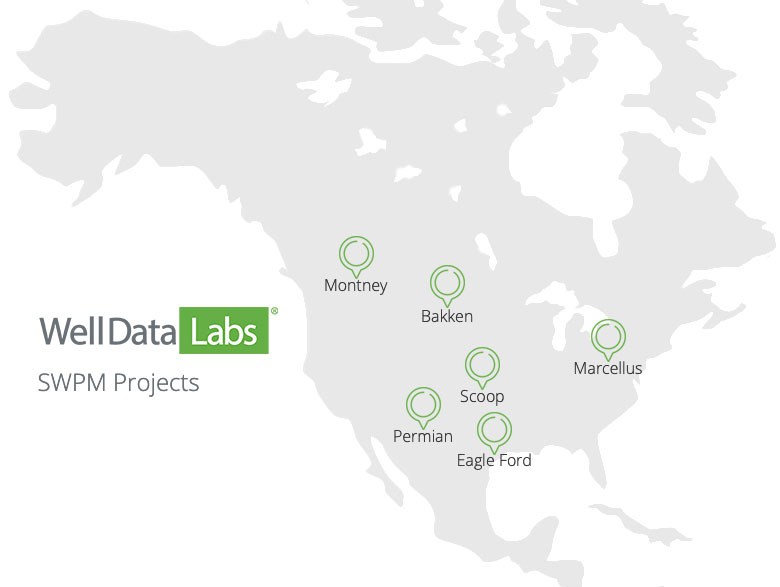

Thanks to the conductive nature of the sealed wellbore, it can pick up subtle pressure responses (down to 1-2 psi). In turn, this information can be fed through the proprietary algorithms developed in conjunction with Devon Energy, to provide valuable data on what is happening below the surface. It also creates a remarkably flexible tool. To date, Well Data Labs has performed SWPM with clients across North America to help them learn how to optimize for the following completion variables:

Thanks to the conductive nature of the sealed wellbore, it can pick up subtle pressure responses (down to 1-2 psi). In turn, this information can be fed through the proprietary algorithms developed in conjunction with Devon Energy, to provide valuable data on what is happening below the surface. It also creates a remarkably flexible tool. To date, Well Data Labs has performed SWPM with clients across North America to help them learn how to optimize for the following completion variables:

-

-

- Fracture half-length

- Stage spacing

- Fluid composition

- Rate cycling

- Perforation/cluster design

- Well spacing

-

Offset Pressure Analysis (OPA)

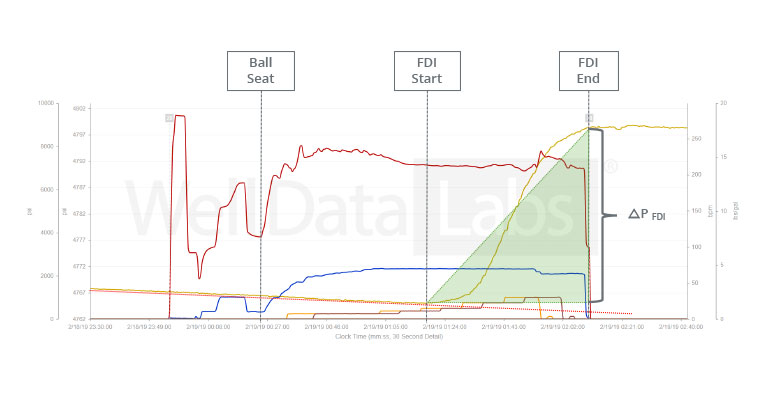

The other fracture diagnostic option offered by Well Data Labs is Offset Pressure Analysis (OPA). It provides valuable data to help detect and diagnose fracture driven interactions (FDIs) using an offset well, which is connected to the reservoir (often has already been completed). This provides an advantage in that there isn’t a disruption to a completion schedule associated with setting aside an uncompleted well to serve as a monitor. The downside, however, is that the closest distance between the active and monitor wells is difficult to determine because the fluid/fractures are moving through legacy well fractures (in other words, rock that has already been stimulated).

Nevertheless, there is valuable data to be gleaned from OPA. This tool is often used to identify fracture shadowing or fracture to fracture connections between the monitor well’s fracture network and the active well’s fracture network. Using the models and algorithms that Well Data Labs has patented, this information can be correlated with specific events taking place within the treatment well. For example, perhaps diverter is causing a runaway fracture from the active treatment well within a particular zone. This information can be particularly useful to prevent additional FDIs from occurring within your development.

Multi-well timeline – analyzing the fracture interaction

Both fracture diagnostic options provide valuable information that can help drive positive EUR in the oilfield. It’s important to understand your goals and what you would like to learn before selecting the fracture diagnostic for the job. If you’d like to learn more about which fracture diagnostic option is right for your situation, feel free to reach out to us at Well Data Labs. We’re here as a thought partner to drive your success.

Got a fracture diagnostic dilemma?

Our Fracture Diagnostic Decoder is a handy tool to help determine the data acquisition methods that are best for evaluating resource uncertainties. Download it here.

Sources

“Breakthrough Technology Uses Pressure Monitoring To Diagnose Cluster Efficiency,” American Oil & Gas Reporter, April 2020

“Monitoring the Pulse of a Well Through Sealed Wellbore Pressure Monitoring, a Breakthrough Diagnostic With a Multi-Basin Case Study,”, 2020, SPE-199731-MS

“Horizontal Well Frac-Driven Interactions: Types, Consequences, and Damage Mitigation,” Ali Daneshy and George King, Pet Technol 71 (2019): 45–47, SPE-0619-0045-JPT

“Leveraging Cloud-Based Analytics in Active Well Defense Projects and Automated Pressure Response Analyses,” Pete Bommer, Jessica Iriarte, Marc Bayne, Colby Cline, Alberto Ramirez, and Mary Van Domelen. Paper presented at the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, Texas, USA, February 2020

“Evaluating Primary-Infill Well Performance After Frac Mitigation Using Fracture-Type Diagnostics in the Midland Basin Wolfcamp Shale,“ Yvonne Scherz, Yogashri Pradhan, Michael Rainbolt, and Thomas Johnston. Paper presented at the SPE/AAPG/SEG Virtual Unconventional Resources Technology Conference, July 2020

Sealed Wellbores and the Unlikely “Breakthrough” Behind Cheap, Accurate Fracture Diagnostics, Journal of Petroleum Technology, April 2020

How can we help?

If you or your team would like to learn more about the SWPM and OPA services offered by Well Data Labs, we would be happy to discuss your specific use case further. We currently offer SWPM as a post-job analysis and plan to make it available in real-time in the near future.

For more information about our Professional Services, or if you have a need not covered above, send us an email or give us a call at (720) 662-7771. Let us know what we can do to help you!