The newest fracture diagnostic on the market: how it works and what it can do for your completion operations

The Upstream Oil & Gas Industry has seen its share of innovation and revolution over the past several decades. From the shale revolution allowing operators to efficiently access tight formations to the adoption of data-driven approaches to completion operations, there is no shortage of examples. The driving force behind these changes has always been a relentless push toward operational and capital efficiency. In an industry that has seen its share of boom and bust cycles, those that are most streamlined have the best staying power. It is with this central tenet in mind that the patent-pending Sealed Wellbore Pressure Monitoring (SWPM) process was born through the efforts of innovative completion engineers at Devon Energy.

This innovative technique utilizes a sealed wellbore (filled with low compressibility fluid) to act like an underground antenna. As hydraulic fractures interact with the sealed wellbore, there are discernable pressure changes that can be picked up from within, providing valuable data. Proper SWPM execution requires establishing a closed system without perforations connected to the formation being stimulated, along with a sealed casing. With this, a surface or downhole gauge can collect and transmit the necessary data to evaluate interactions with treatment wells that are actively being completed.

The major aim of all fracture diagnostics is to optimize for cluster efficiency. Variations that occur along a lateral can be influenced by any number of constantly changing factors. This, in turn, has repercussions for drainage patterns and the very economics of the well. This is why operators are willing to pay up to and sometimes over $1M for certain types of diagnostics within a single project.

What can be accomplished with data captured during the SWPM process to maximize well economics? Here is a sample of some of the ways that this data has been used to date:

Qualitative fluid distribution

Fracture count in the far-field

Fracture height and fracture half-length

Depletion identification and mitigation

Fracture model calibration

Fracture closure time estimation

“SWPM provides operators with a cost-effective, scalable method to evaluate fluid distribution. SWPM will serve as a critical step towards real-time completion optimization, allowing operators to customize every stage of their completion to maximize the value of their wells.”

Kyle Haustveit, Completions Engineer, Devon Energy

This process has been validated by engineers at Devon Energy across more than 3,000 stages in every major US basin1. Further, it has been validated by major established fracture diagnostic techniques, including Distributed Temperature and Distributed Acoustic Sensing (DTS-DAS), Cross Well Strain, and microseismic monitoring2.

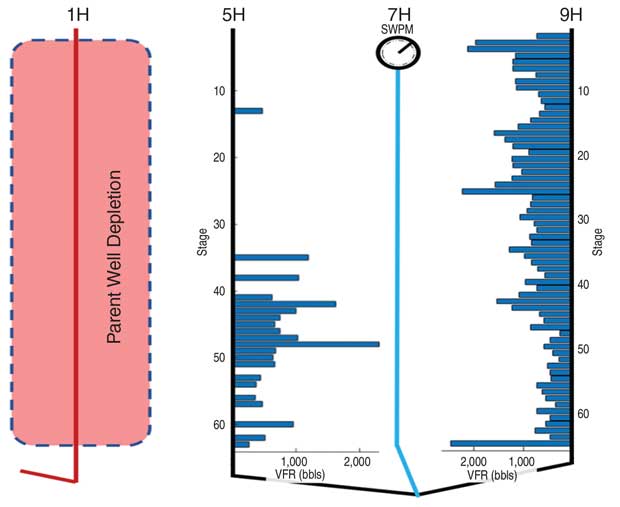

The primary measurement obtained from an SWPM evaluation is the Volume to First Response (VFR) from each individual stage in the active treatment wells. Large VFRs indicate good cluster efficiencies and controlled fracture growth. Small VFR indicates rapid communication between the treatment wells and the SWPM monitor well.

Comparison of Treatment Well VFRs

The image here provides a visual of fracture asymmetry based upon by-stage volume to first response (VFR) for two wells.

Image courtesy of Devon Energy

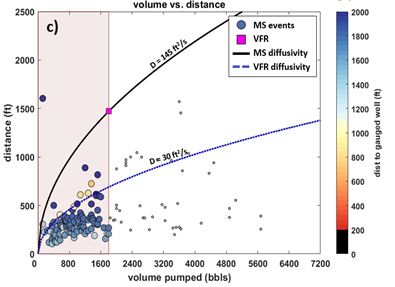

The measured VFRs can be used to quantify the dominant fracture growth rates by translating the time to first response to an apparent fracture diffusivity.

Image courtesy of Devon Energy

Dominant Fracture Apparent Diffusivity

Today’s challenging environment requires using efficient, affordable tools to maximize the value of completion operations. The SWPM process represents exactly that, and as the exclusive commercial provider of this service, Well Data Labs invites you to partner with us to take your operations to the next level.

Want to learn more? Visit our Fracture Diagnostics web page, or send us an email.

Get our handy Fracture Diagnostic Decoder, click here to get it sent to your inbox.

Additional resources

1Breakthrough Technology Uses Pressure Monitoring To Diagnose Cluster Efficiency, American Oil & Gas Reporter, April 2020

2 Monitoring the Pulse of a Well Through Sealed Wellbore Pressure Monitoring, a Breakthrough Diagnostic With a Multi-Basin Case Study, 2020, SPE-199731-MS

Sealed Wellbores and the Unlikely “Breakthrough” Behind Cheap, Accurate Fracture Diagnostics, Journal of Petroleum Technology, April 2020

Devon Energy and Well Data Labs to Commercialize Sealed Wellbore Pressure Monitoring, Press Release, June 2, 2020

How can we help?

If you or your team would like to learn more about the SWPM service offered by Well Data Labs, we would be happy to discuss your specific use case. We currently provide SWPM as a post-job analysis and plan to make it available in real-time this fall.

For more information about our Professional Services, or if you have a need not covered above, send us an email or call (720) 662-7771. Let us know what we can do to help you!