Integrating Rock Properties and Fracture Treatment Data to Help Optimize Completions Design

In case you missed this paper on the Society of Petroleum Engineers (SPE) OnePetro website, a team of experts from Hawkwood Energy, FractureID, and Well Data Labs describe how engineers can optimize their completions design by using a multivariate approach to understand unique rock types and their impact on completion responses.

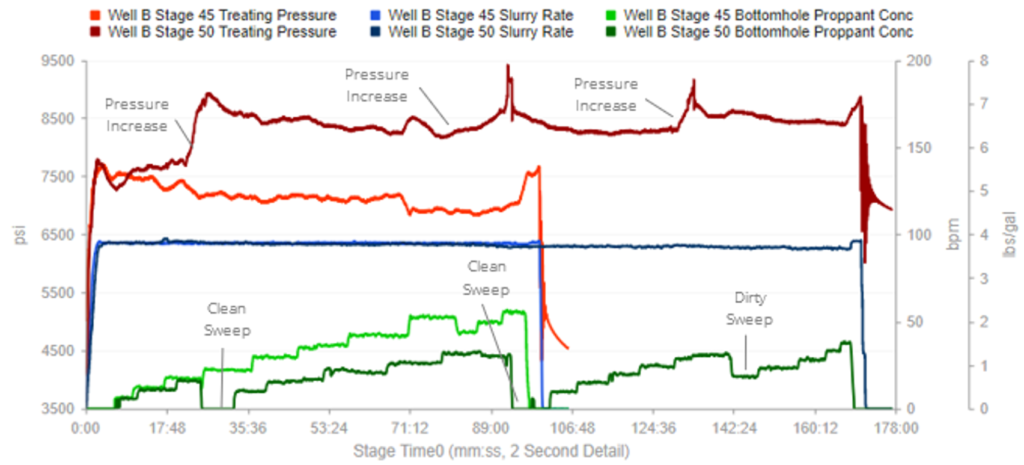

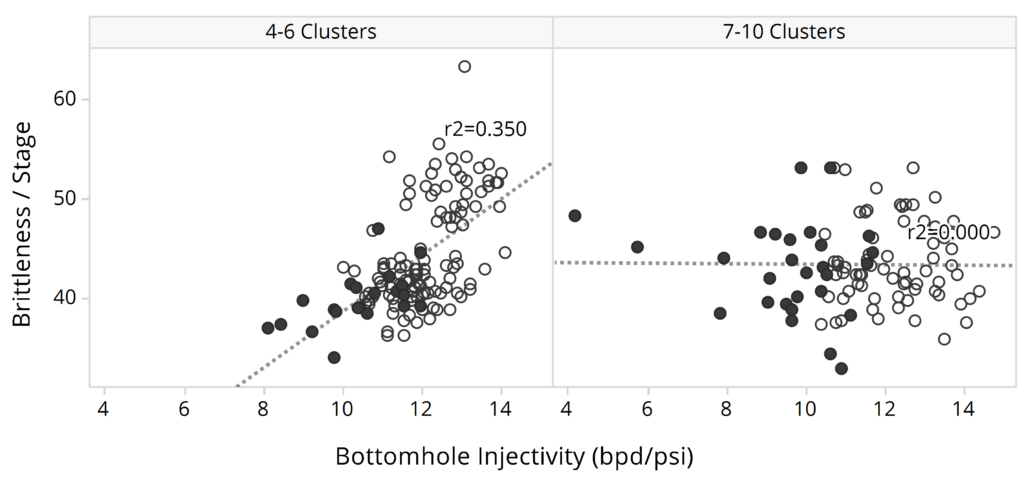

In this study of six Eagle Ford wells, proprietary high-resolution geomechanical data captured at the drill bit using FractureID’s Drillbit Geomechanics™ technology and high-frequency fracture treatment data were standardized, QC’ed, normalized, and analyzed using Well Data Labs’ frac data management and analysis platform. The approach combined critical rock properties, high-frequency fracture treatment data including treating pressures, rates, and fluid and proppant volumes, and a fast-analytical methodology to analyze the geomechanical and completions database. Using these methods, the team concluded that variations in rock properties could directly impact fracture treatment responses. While many factors can affect treating pressures and injectivity, the primary factor identified in this dataset was low brittleness and high-stress differential across a stage (Figures 1 and 2). Injectivity is driven by a complex interplay of geologic and mechanical factors that may include poor perforation efficiency, near-wellbore complexity, in-situ stress, and rock ductility.

Figure 1 – Fracture treatment plot (from two heelward stages of one of the wells) showing the different pressure behavior when rock properties are more variable or more homogeneous along the stage.

Figure 2 – Average bottomhole injectivity vs. average brittleness of each stage of the six wells split by the number of clusters in the perforation design. Filled circles represent the stages where there was a screen out or a significant pressure increase occurred when the proppant reached the perforations.

In the Eagle Ford target in this study, the team hypothesized that clay-associated ductility played a significant role in injectivity and completions issues (screen outs); however, MWD gamma ray, as a proxy for clay volume, yielded no correlation to injectivity. To investigate the impact of clays and ductility on injectivity, a petromechanical workflow was designed using vertical transverse isotropy or VTI anisotropy calculated from the near-bit accelerations.

The authors concluded that the relationship between anisotropy-derived brittleness and screen outs is because the acceleration data is inherently sensitive to texture as well as mineralogy. The gamma ray-derived brittleness, or clay volume, is driven solely by the atomic composition. This relationship implies that the laminarity of the rock, and not just the mineralogy, creates challenges for the completion. The team also determined that high differential pressure across the treatment could cause perforations in lower stressed rock to break down taking the majority of the treatment while perforations in higher stress rock could be left unstimulated.

Using the method described in the paper, engineers can better predict trouble stages, optimize proppant placement, and improve operational efficiencies. To obtain the full version of the paper visit OnePetro here.

We want to thank Hawkwood and FractureID for their collaboration on this paper.