by Well Data Labs | Feb 18, 2026 | ChatWDL, Data Integration, Data Science, Industry Insights, Machine Learning

Quick Summary (TL:DR) Understanding Generative AI and Foundation models is critical to unlocking AI’s value while avoiding risks around accuracy, bias, and data security. As enterprise AI adoption accelerates, a new set of technology terms has entered the mainstream....

by Well Data Labs | Feb 3, 2026 | ChatWDL, Data Analytics, Data Integration, Data Science, Machine Learning

As oil and gas companies adopt AI and large language models (LLMs), data privacy and ownership have become top concerns. One term gaining traction across the industry is Zero Copy. What Does Zero Copy Mean? Zero Copy refers to an architecture where data is never...

by Well Data Labs | Nov 24, 2025 | Completions, Data Analytics, Data Integration, Data Science, Industry Insights, Machine Learning, News, Spotlight Series, Uncategorized

The past year has marked a real step change in generative AI’s ability to handle math, statistics, and day-to-day analytics. Work that once demanded manual effort or niche tools is now within reach with the right data foundation and thoughtful guardrails. The oil and...

by Well Data Labs | Sep 25, 2025 | Completions, Data Analytics, Data Science, Fracture Diagnostics, Industry Insights, Machine Learning, News, Spotlight Series, Uncategorized

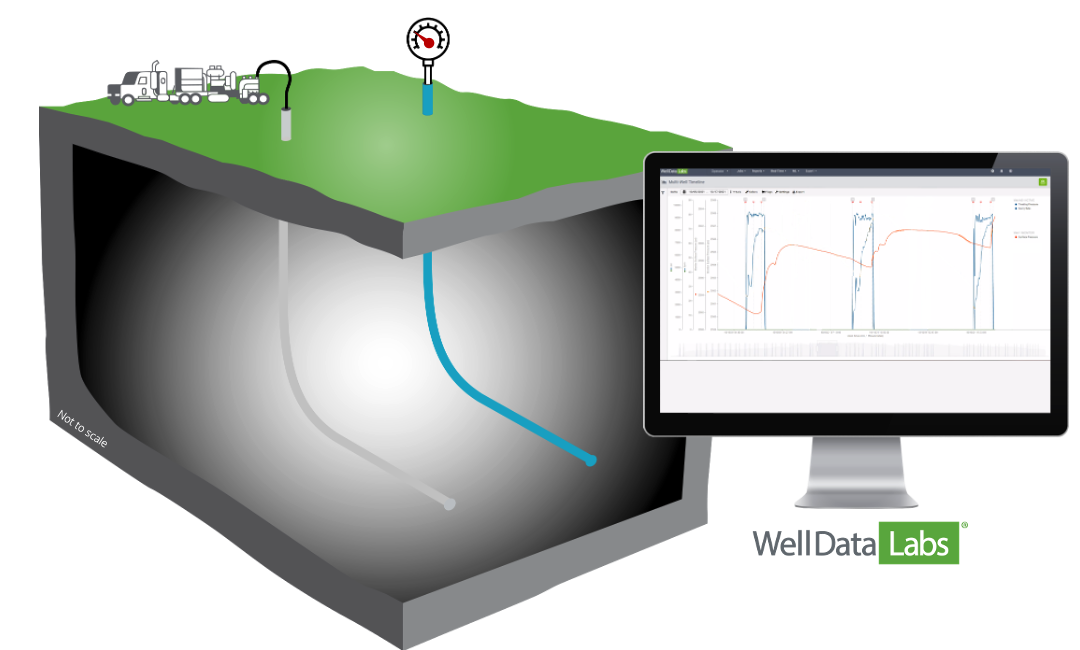

Sealed Wellbore Pressure Monitoring (SWPM) is getting a lot of attention in completions, and for good reason. It gives operators a clear window into fracture growth, cluster efficiency, and parent-child interactions without the big price tag of fiber or tracers. On...

by Well Data Labs | Sep 17, 2025 | Completions, Data Analytics, Data Integration, Industry Insights, IT, News, Real-Time Frac, Spotlight Series

Our team had a blast joining the “BDE Podcast” to chat about our new partnership with NOV and why it’s a big deal for operators. NOV’s hardware now aggregates and synchronizes data from coil tubing, wireline, pump down, and offset sensors, all in...

by Well Data Labs | Aug 12, 2025 | Completions, Data Analytics, Data Integration, Data Science, Machine Learning, News, Real-Time Frac, Uncategorized

NOV and Well Data Labs (WDL) have announced a collaboration that transforms the management and visualization of operational fracturing data. By combining NOV’s Max Completions™ proven aggregation hardware with WDL’s Al-driven data analytics platform, this...

by Well Data Labs | Aug 1, 2025 | Data Analytics, Data Integration, Data Science, Machine Learning, News

Well Data Labs (WDL) has officially launched ChatWDL, a groundbreaking AI reasoning agent purpose-built for the oilfield. ChatWDL empowers executives to proactively drive workplace innovation through autonomous, agentic workflows, eliminating the delays associated...

by Mary Van Domelen | Mar 3, 2025 | Completions, Data Analytics, Data Science, Machine Learning

Don’t wait until plug drill-out to discover casing deformation The trend in hydraulic fracturing has been to push the envelope on drilling longer horizontal laterals with an ever-increasing number of stages, clusters, proppant, and fluid volumes. As completion...

by Well Data Labs | May 25, 2023 | Data Integration

The oil and gas industry is constantly seeking ways to optimize and improve production while keeping costs low and reducing environmental impacts. In the Eagle Ford shale, one of the most significant challenges faced by operators is determining the most efficient...

by Well Data Labs | Mar 15, 2022 | Completions, Data Analytics, Data Science, Fracture Diagnostics, Machine Learning, Real-Time Frac

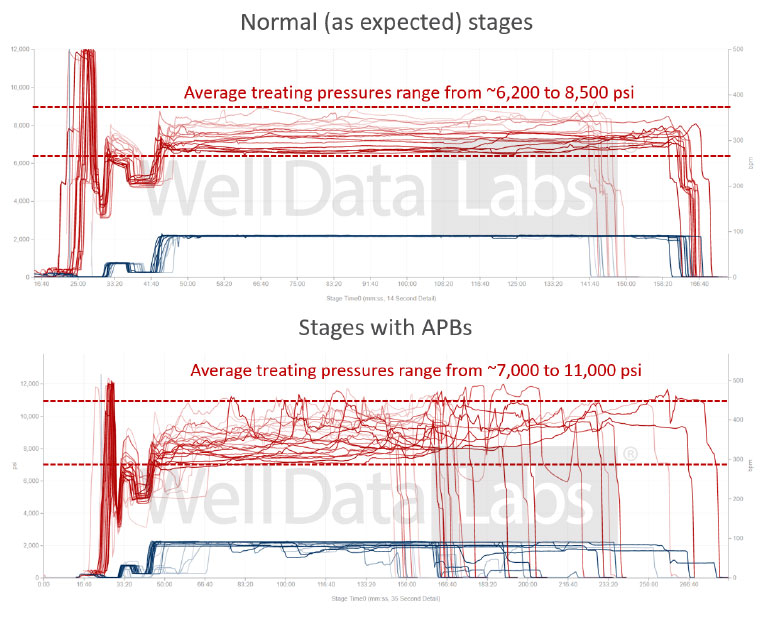

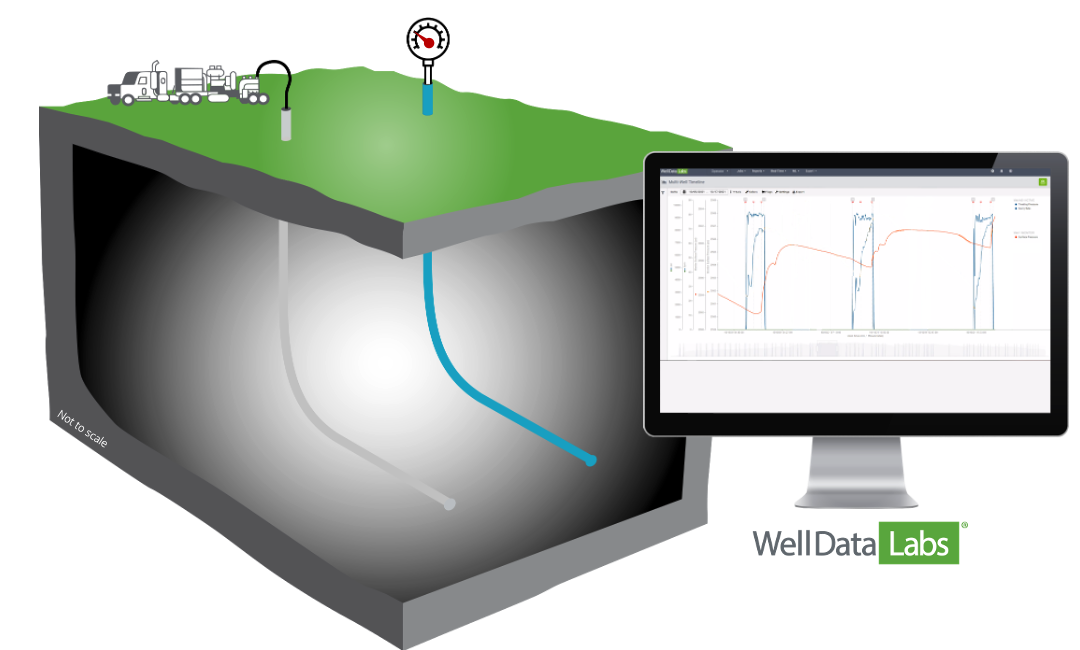

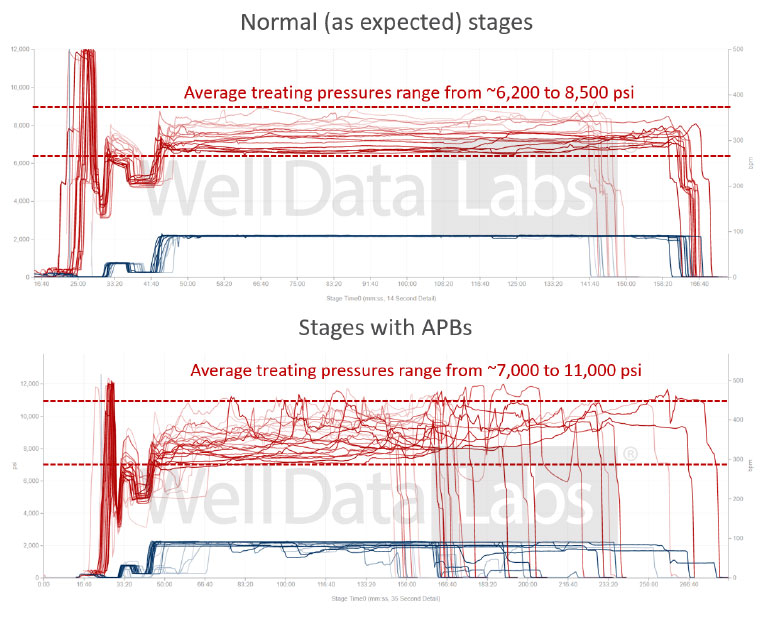

Summary of the SPE HFTC 2022 paper, “Automating a Breakthrough Technology for Real-Time Diagnostics: Sealed Wellbore Pressure Monitoring” The SWPM (sealed wellbore pressure monitoring) process is precisely what the name implies – measuring pressure...